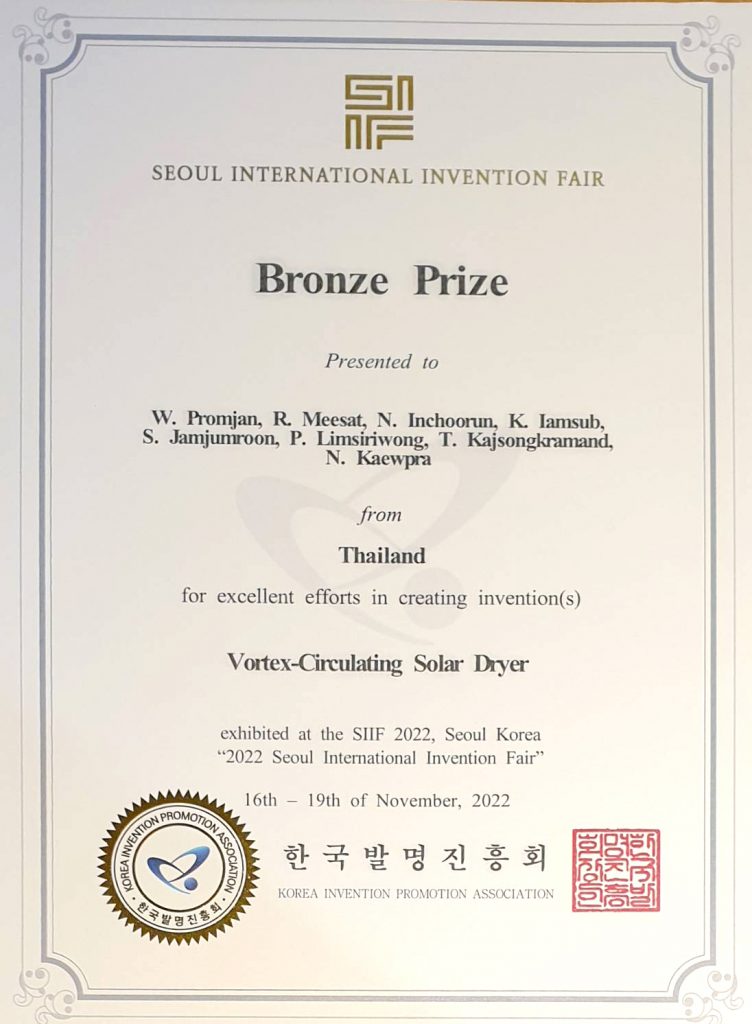

Dr. Rewadee Meesat, a senior researcher, and Mr. Weerayuth Promjan, a researcher, from the Expert Centre of Innovative Health Food (InnoFood), Thailand Institute of Scientific and Technological Research (TISTR), Ministry of Higher Education, Sciences, Research and Innovation (MHESI), received ‘Bronze Prize’ for their research of ‘Vortex-Circulating Solar Dryer’, under the Project ‘TISTR Krua Peng Pun’, in ‘Seoul International Invention Fair 2022 (SIIF 2022)’, held during 16 – 19 November 2022, in South Korea. The research was selected by the National Research Council of Thailand (NRCT) to join SIIF 2022.

SIIF is an international exhibition and showcase of inventions held in Seoul, South Korea, for market purposes and invention promotions, since 2002. It is hosted by the Korean Intellectual Property Office (KIPO), organized by the Korea Invention Promotion Association (KIPA), and supported by the World Intellectual Property Organization (WIPO) and its partner countries. Now it serves a large platform for worldwide researchers and inventors to share their ideas and show new products to the manufactures, investors and distributors.

‘Vortex-Circulating Solar Dryer’ resulted from integrated collaboration among TISTR units: an Expert Centre of Innovative Health Food (InnoFood), an Expert Centre of Innovative Herbal Products (InnoHerb), an Expert Centre of Innovative Agriculture (InnoAg), and an Expert Centre of Innovative Industrial Robotics and Automation (InnoRobot). It is suitable for dying foods at temperature up to 60 degrees Celsius, such as sun-dried pork, salted fish, dried shrimp, dried squid, including dried fruits, such as banana, mangoes, longan, jackfruit and dragon fruit, as well as, herb types of rhizomes, leaves and flowers, such as ginger, turmeric, pandanus leaf, paniculate, butterfly pea.

Its strong features: aerodynamics design to support air circulation and heat dissipation inside the drying chamber to be consistent and thorough. It can support 10 raw material trays with 5 kg. per tray, and covers 2 X 2 square meters for installation to save utility space. It has more than 5 – 10 times drying rate of conventional solar ovens and accepts heat power from LPG gas in case there is no sunlight.

Its components and operations: 1.) External structure has a vertical cylindrical shape made from translucent polycarbonate sheet, which is able to absorb solar heat power in all directions and store the power in the drying chamber; 2.) internal structure has 10 layers of raw material trays, sized 1 X 1 square meter, which is able to support raw materials up to 50 kg. per time; 3.) lower part is equipped with an aeration system for air circulation inside the drying chamber. Aeration rate is controlled by open-close lids; 4.) a ventilator works with outside wind power to create airflow inside the drying chamber to suck moisture from raw materials, and control temperature inside the drying chamber by gate valve; and 5.) in case there is no sunlight, a heat power system from LPG gas is installed outside the drying chamber to provide heat through heat dissipation plates.

If you need further information, or have any queries, or be interested in its technology transfer for commercialization, please contact Mr. Weerayuth Promjan, a researcher of an Expert Centre of Innovative Health Food (InnoFood), via email: weerayuth_p@tistr.or.th

Views: 1438